Imikhiqizo

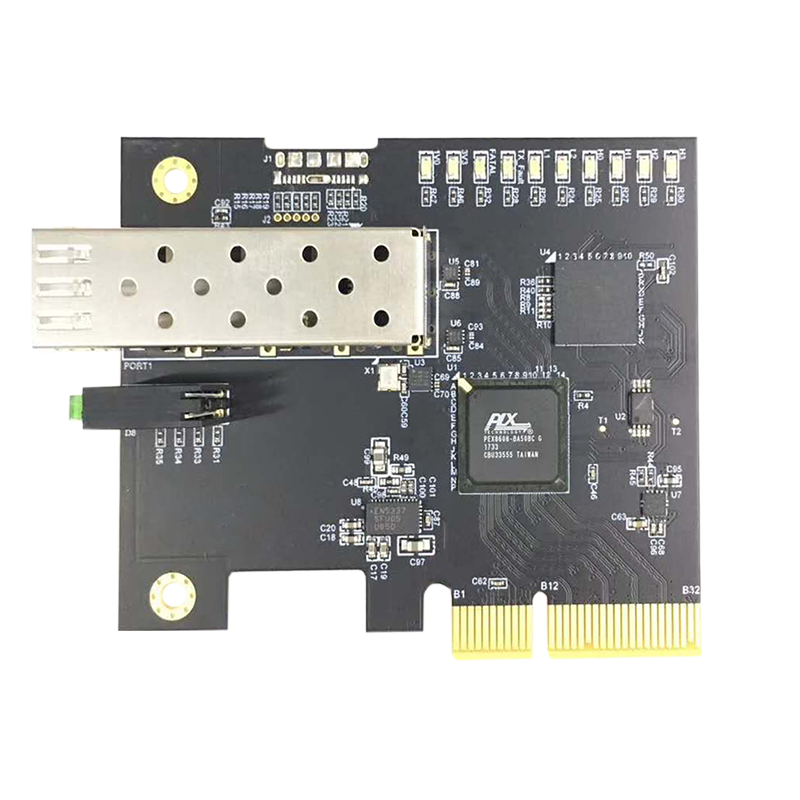

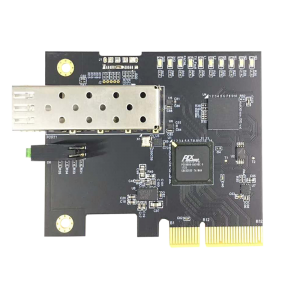

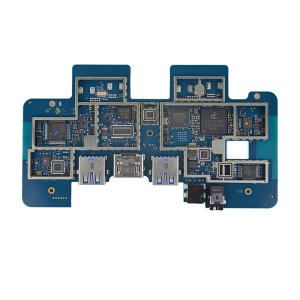

I-Golder Finger PCBA Printed Circuit Board Assembly

I-Photoplate: Kusetshenziswa ubuchwepheshe be-photoplate ukudlulisa amaphethini wesekethe ku-substrate.Impahla yethusi eyeqile isuswa i-photomask kanye ne-chemical etching ukwenza iphethini yesifunda oyifunayo.Ukwelashwa okufakwe ngegolide: Ukwelashwa okufakwe ngegolide kwenziwa engxenyeni yomunwe wegolide ukuze kuthuthukiswe ukuguquguquka kwawo kagesi nokumelana nokugqwala.Ngokuvamile, indlela ye-electroplating isetshenziselwa ukufaka izinto zensimbi ngokufanayo ebusweni bomunwe wegolide.Ukushisela nokuhlanganisa: Weld futhi uhlanganise izingxenye kanye nebhodi le-PCB ukuze uqinisekise ukuthi amalunga e-solder aqinile futhi anokwethenjelwa.Sebenzisa i-surface mount technology (SMT) noma ubuchwepheshe bokunamathisela be-plug-in, khetha ngokuya ngezidingo ezithile.Ukuhlolwa kwekhwalithi nokuhlolwa: Ukuhlolwa kwekhwalithi okuqinile kanye nokuhlolwa kwenziwa ngesikhathi senqubo yokukhiqiza ukuze kuqinisekiswe ukuthi ibhodi le-PCB lomunwe wegolide lihlangabezana nokucaciswa kanye nezidingo zekhwalithi.

Kubandakanya ukuhlola okubukwayo, ukuhlolwa kwesici sikagesi, ukuhlolwa kwe-impedance, njll. Ukuhlanza nokunamathisela: Hlanza i-Goldfinger PCB eqediwe ukuze ususe ukungcola okungaphezulu nezinsalela.Ukwelashwa kwe-anti-corrosion coating kwenziwa njengoba kudingekile ukuze kuthuthukiswe ukumelana nokugqwala kwebhodi le-PCB.Ukupakisha nokulethwa: Phakamisa kahle i-Golden Finger PCB eqediwe ukuze uvimbele ukulimala ngokomzimba noma ukungcoliswa.Ngemva kokuqeda ukuhlola kokugcina, letha kukhasimende ngesikhathi.Inqubo yokukhiqiza ibhodi le-Goldfinger PCB idinga ukunemba okuphezulu nokulawula okuqinile ukuze kuqinisekiswe ikhwalithi yomkhiqizo nokuzinza.Sizosebenza ngokuhambisana ngokuqinile nenqubo engenhla ukuze sikunikeze imikhiqizo yebhodi ye-PCB yeminwe yegolide ephezulu.