Sinikezela ngeenkonzo zokuwelda ze-PCBA zokuqinisekisa ukuba iimveliso zakho ze-elektroniki zikwelona nqanaba libalaseleyo ngokwemigangatho kunye nokusebenza.

Kutheni ukhetha inkonzo yethu ye-PCBA Welding?

●Ubuchwephesha obuphezulu be-welding: Sineqela lobugcisa elinamava, elinobuchule kwiindlela ezahlukeneyo zokuwelda kunye nobuchule, kubandakanywa iteknoloji ye-surface Mount (SMT) kunye ne-plug-in technology (THT).

Ingaba yinto encinci yokunyuka kwendawo okanye iplagi enkulu, sinokugqiba inkqubo ye-welding ngokuchanekileyo nangempumelelo.

●Ukulawulwa komgangatho ongqongqo: Sisebenzisa inkqubo engqongqo yokulawula umgangatho ukuze siqinisekise ukuba yonke inkqubo yokuwelda idibana nemigangatho yomgangatho.

Sisebenzisa izixhobo zokuvavanya eziphambili kunye neendlela zokuqhuba uvavanyo olubanzi kunye nokuqinisekiswa koqhagamshelwano oludibeneyo lwe-solder, umgangatho we-welding kunye nofakelo oluchanekileyo lwamacandelo ukuqinisekisa ukuthembeka kwemveliso kunye nokusebenza.

●Izisombululo ezilungiselelweyo: Sinokubonelela ngezisombululo ze-welding ye-PCBA ngokweemfuno zabathengi.

Sisebenza ngokusondeleyo kunye nabathengi bethu ukuqonda iimfuno zabo ezithile kunye nokulindela, kwaye sinikeze iingcebiso ezifanelekileyo kunye nenkxaso yobugcisa ukufezekisa iziphumo ezilungileyo ze-welding.

Phambi kweMveliso

KwiMveliso

Emva kweMveliso

Uphononongo lwedatha

Ukulungiswa kwefayile

Ukungena kweBOMUkuthenga Isicelo

UQinisekiso lweSampuli (iNjineli yeProjekthi, uMthengi) Uvavanyo-mveliso, ukuveliswa kobuninzi (Injineli yeprojekthi ilandela yonke inkqubo)

IsiShwankathelo seProjekthi(Rekhoda ifayile yeeodolo eziphindayo) Ulandelelo lwabathengi (inkonzo yasemva kokuthengisa)

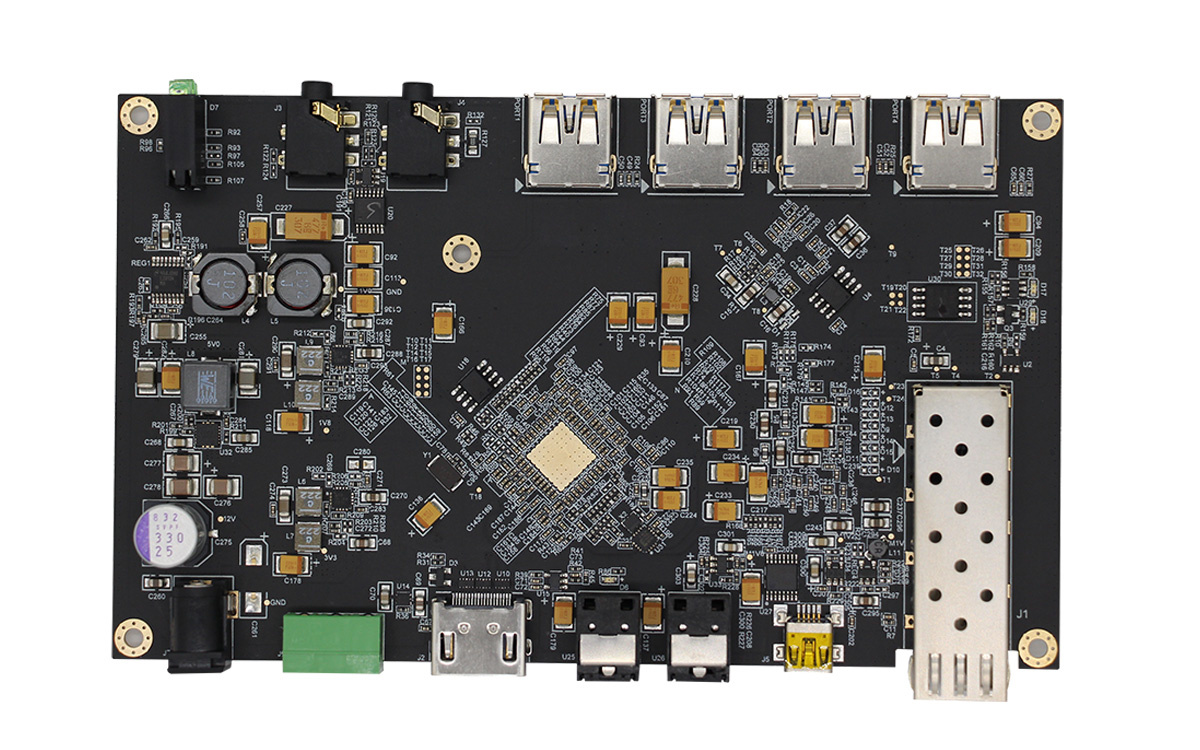

One-Stop Pcba Processing And Manufacturing Service Provider

Umgca we-SMT

AOI

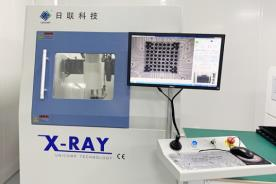

X-RAY

I-lead-free reflow soldering

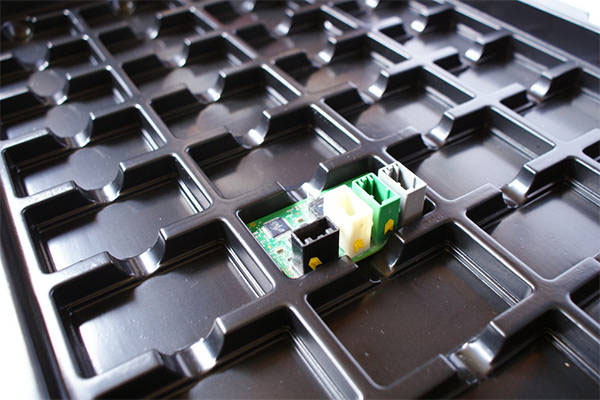

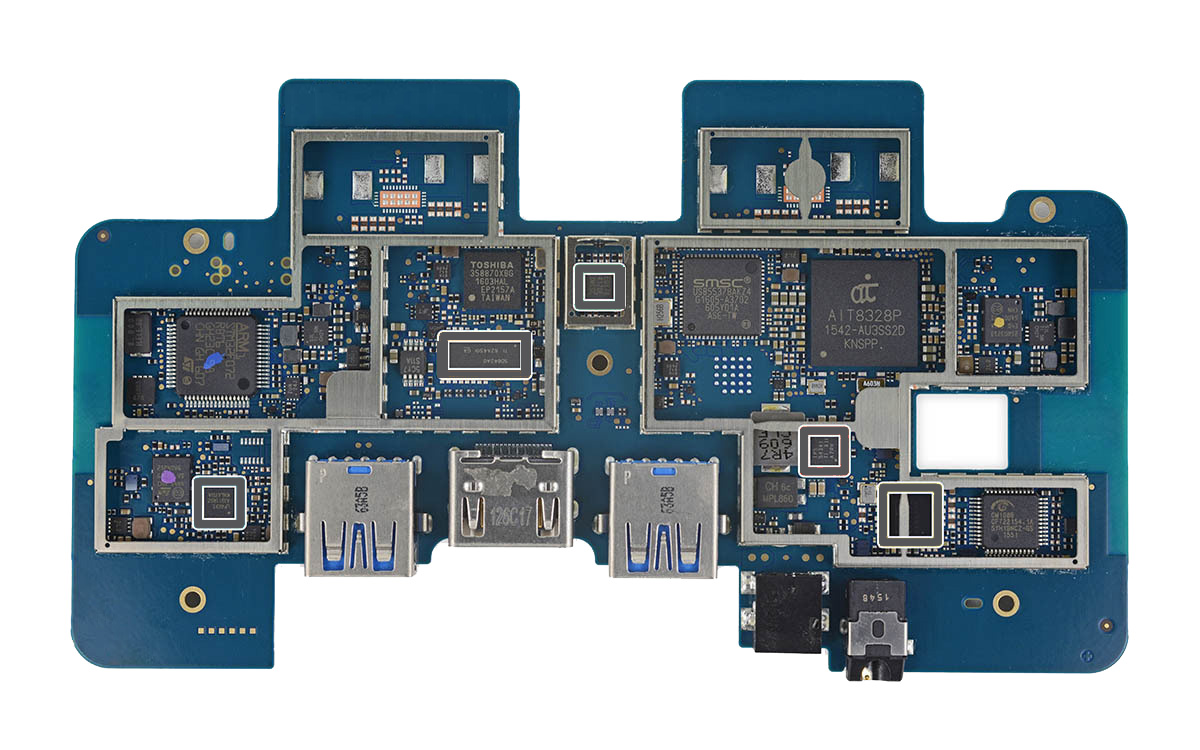

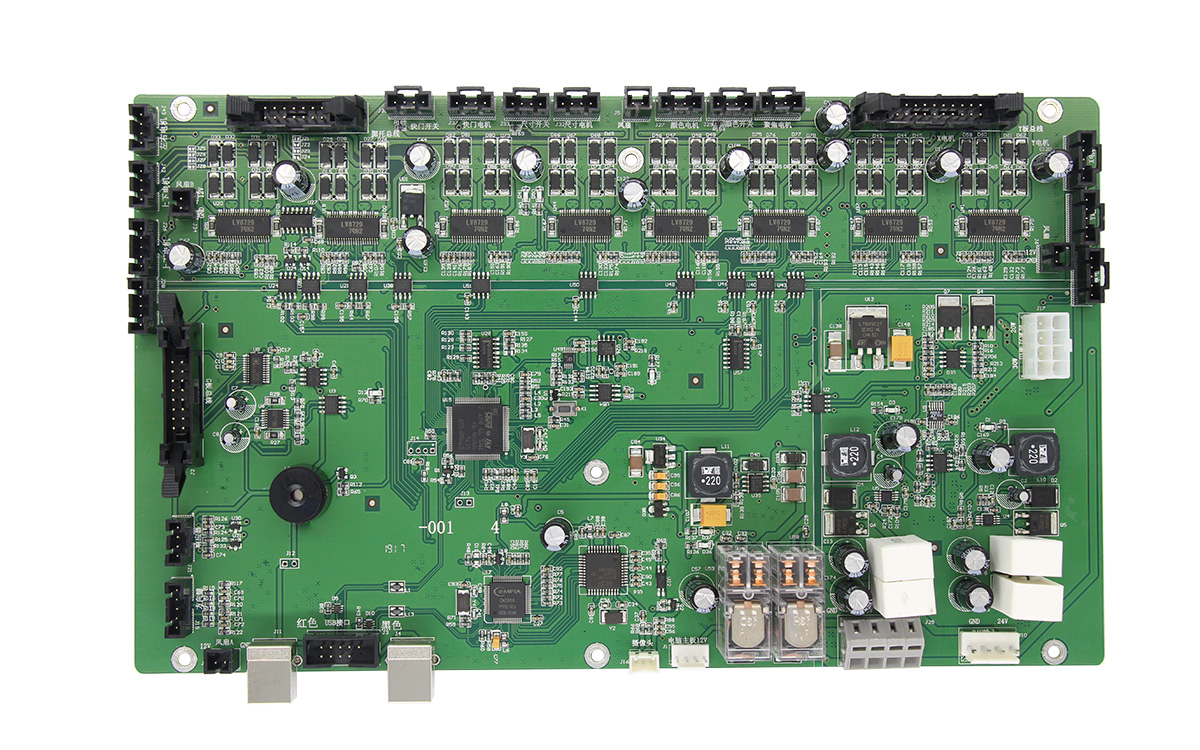

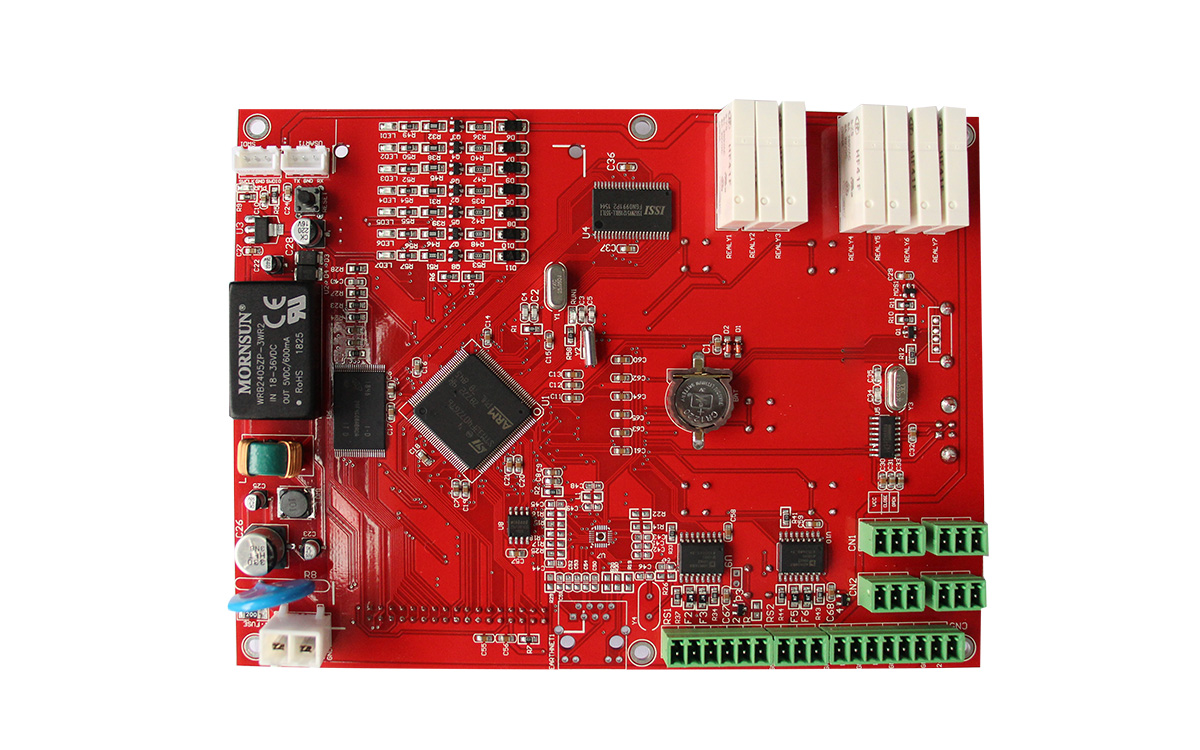

PCBA Isiboniso seCase esingaphelelanga

Ishishini le-Aerospace

Ishishini loLawulo loShishino

I-Electronics yabathengi

I-Electronics yabathengi

Ishishini lezonyango

Ushishino lweemoto

Indawo yovavanyo lwe-PCB yindawo ekhethekileyo egcinwe kwibhodi yesekethe eprintiweyo (PCB) yokulinganisa umbane, ukuhanjiswa komqondiso kunye nokuxilongwa kwempazamo.

Abathengi banokuyila iindlela zovavanyo ngokwamanqaku ovavanyo, kwaye siya kwenza uhlengahlengiso lovavanyo lokulinganisa olusebenzayo.

☑ Imisebenzi yabo ibandakanya: ukulinganisa kombane Indawo yokuvavanya ingasetyenziselwa ukulinganisa i-voltage, yangoku, i-impedance kunye nezinye iiparamitha zombane zesekethe ukuqinisekisa ukusebenza okuqhelekileyo kunye nokusebenza kwesekethe.

☑ Ugqithiso loMqondiso:Indawo yokuvavanya ingasetyenziselwa njengepini yesignali ukudibanisa nezinye izixhobo zombane okanye izixhobo zokuvavanya ukuphumeza igalelo lesiginali kunye nesiphumo.

☑ Ukuqinisekiswa koyilo:

Ngokusebenzisa indawo yovavanyo, qinisekisa ukuchaneka kunye nokusebenza koyilo lwePCB ukuqinisekisa ukuba ibhodi yesekethe isebenza ngokweemfuno zoyilo.

☑ Ukuxilongwa kobuphene:

Xa impazamo yesekethe isenzeka, unokukhangela impazamo ngokusekwe kwindawo yovavanyo ukunceda iinjineli ukuba zifumane unobangela kunye nesisombululo sempazamo.

☑ Ukulungisa ngokukhawuleza:

Xa izinto zesiphaluka kufuneka zitshintshwe okanye zilungiswe, amanqaku okuvavanya angasetyenziselwa ukudibanisa ngokukhawuleza kunye nokuqhawula iisekethe, ukwenza lula inkqubo yokulungisa.