Products

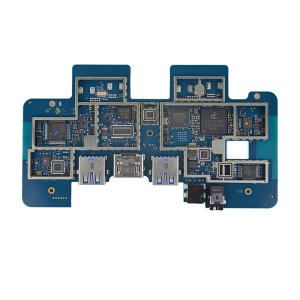

PCBA quality standards for UAV products usually involve the following aspects

Component quality:

The selection and use of high-quality components is crucial to the quality of PCBA. This includes selecting reliable suppliers and conducting the necessary component screening and verification to ensure they meet product specifications and reliability requirements.

Process control:

The PCBA manufacturing process requires strict control to ensure the quality of assembly and soldering. This includes optimizing the production process, controlling the temperature profile, rational use of flux, etc. to ensure soldering quality and connection reliability.

Functional testing:

Comprehensive functional testing of PCBA is an important link to ensure product quality. This includes static testing, dynamic testing, environmental testing, etc. to verify the performance and reliability of the PCBA.

Traceability:

The materials and processes involved in the PCBA manufacturing process should be traceable so that they can be traced and checked when necessary. This also helps ensure product quality and safety.

In addition to the above standards, depending on the needs of specific drone products, PCBA may also need to comply with other industry standards and specifications, such as ISO 9001 quality management system, UL safety certification, etc. Therefore, when formulating PCBA quality standards, it is necessary to combine product requirements, industry standards and customer requirements to ensure that the performance and quality of PCBA reach the best level.

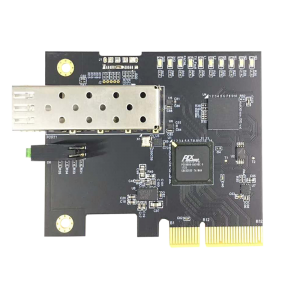

Goldfinger PCB (Printed Circuit Board) is a special circuit board with connectors or sockets for connecting other electronic components or devices. The following are the general process and precautions for gold finger PCB production: Design and layout: According to product requirements and specific specifications, use professional PCB design software to design and layout Golden Finger PCB. Make sure the connectors are positioned correctly, fit properly, and follow board design specifications and requirements.

PCB manufacturing: Send the designed golden finger PCB file to the PCB manufacturer for manufacturing. Considerations include choosing the right type of material (usually a high-quality fiberglass material), board thickness and number of layers, and ensuring that the manufacturer can provide high-quality fabrication services.

Printed board processing: In the PCB manufacturing process, a series of processing procedures are required for the PCB, including photolithography, etching, drilling, and copper cladding. When carrying out these processes, it is necessary to ensure high machining accuracy to ensure the size and surface finish of the gold fingers.

Gold finger production: Using special processes and equipment, conductive materials (usually metal) are plated on the surface of the connector gold finger to increase its conductivity. During this process, temperature, time and coating thickness must be strictly controlled to ensure the quality and reliability of the gold finger.

Welding and assembly: Welding and assembling other electronic components or equipment with golden finger PCB. During this process, care needs to be taken to use proper soldering techniques and equipment to ensure the quality and stability of the connection.

Testing and Quality Control: Conduct comprehensive functional and quality testing on the assembled golden finger PCB to ensure it meets design specifications and product requirements. At the same time, establish a quality control system to carry out strict quality control on each manufacturing link to improve the quality and reliability of Golden Finger PCB.

During the gold finger PCB production process, the following issues need to be paid attention to: Accuracy of dimensions and dimensional tolerances. Ensure the reliability of welding technology and equipment. Gold finger thickness and surface finish. Regularly maintain and clean the connector to ensure its good contact performance. Protective measures during transportation and packaging to avoid damage or deformation. The above are the general process and precautions for gold finger PCB production. For specific operations, it is recommended to carry out detailed planning and control according to product requirements and manufacturer's recommendations.