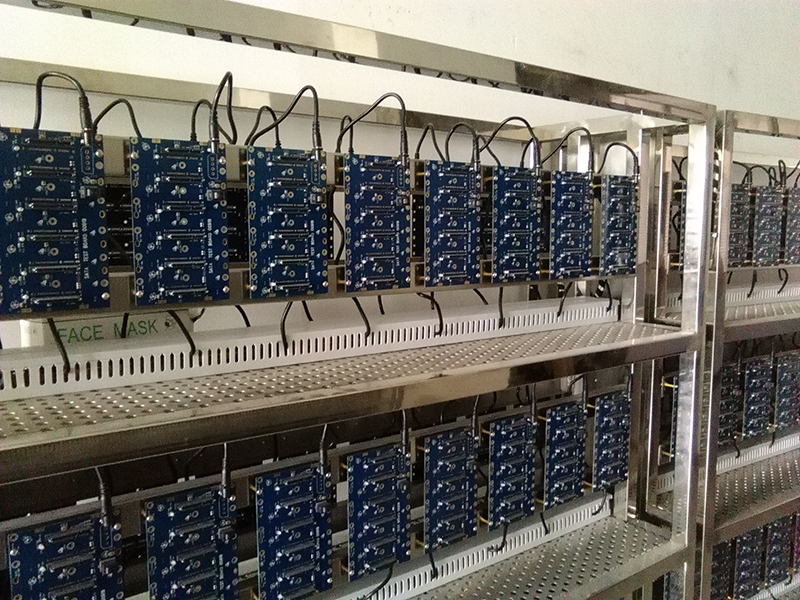

The PCBA aging test is to evaluate its reliability and stability during long-term use.

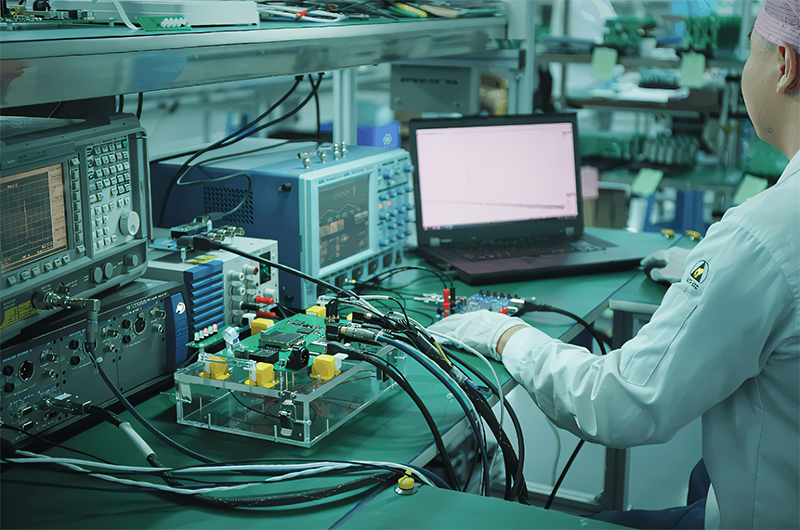

When performing PCBA aging testing, you need to pay attention to the following aspects: Test conditions: Determine the environmental conditions for the aging test, including parameters such as temperature, humidity, voltage, etc., which need to be set appropriately based on the actual use environment.

Test time: Determine the duration of the aging test based on the expected service life of the PCBA and the actual application scenario. In some cases, it is necessary to simulate use for several years or even longer.

Monitoring parameters: During the aging test process, the key parameters of PCBA need to be monitored, such as current, voltage, temperature, etc., in order to evaluate its performance changes and stability.

Data analysis: Fully analyze the data collected during the test to evaluate the performance changes and reliability of PCBA during the aging process.

Result evaluation: Based on the results of the aging test, evaluate the reliability and stability of the PCBA, as well as possible problems and improvement directions.

By reasonably setting aging test conditions, monitoring key parameters, and conducting in-depth analysis of test results, the reliability and stability of PCBA can be effectively evaluated, providing reference and improvement directions for its practical application.

Post time: Dec-19-2023