Ngwaahịa

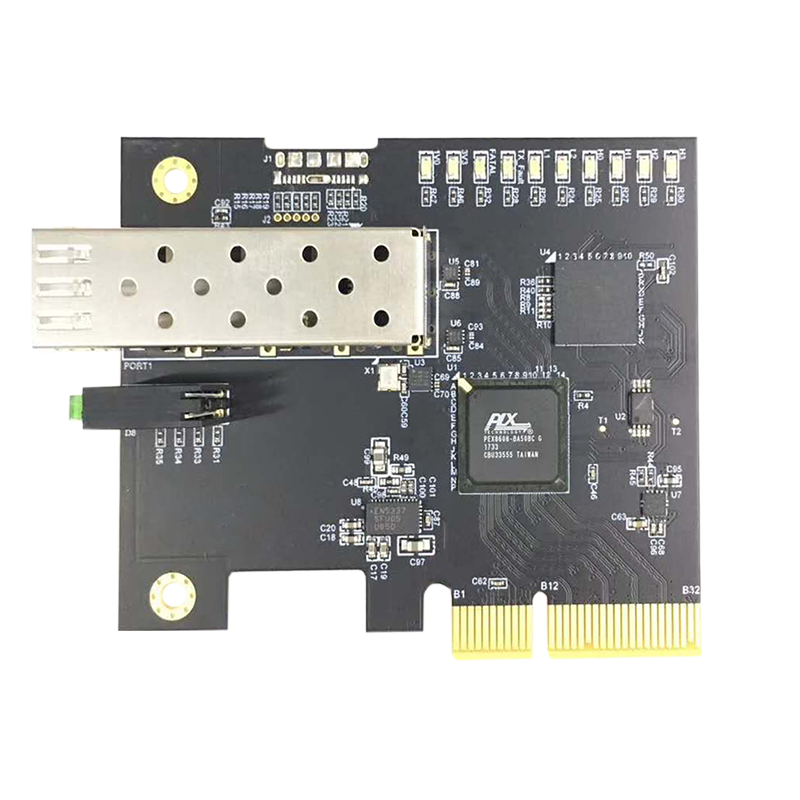

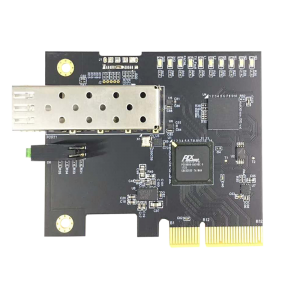

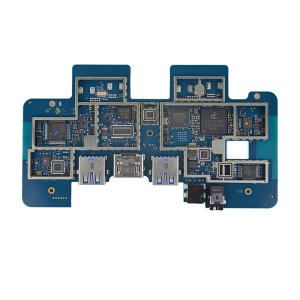

Mkpịsị aka Golder PCBA Ebipụtara Circuit Board Assembly

Photoplate: Iji teknụzụ photoplate nyefee usoro sekit na mkpụrụ.A na-ewepụ ihe ọla kọpa karịrị akarị site na fotomask na kemịkalụ etching iji mepụta ụkpụrụ sekit achọrọ.Ọgwụgwọ ọla edo: A na-eme ọgwụgwọ ọla edo n'akụkụ mkpịsị aka ọla edo iji meziwanye conductivity eletrik ya na nguzogide corrosion.Ọtụtụ mgbe, a na-eji usoro electroplating na-etinye otu ihe eji eme ọla n'elu mkpịsị aka ọla edo.Welding na mgbakọ: Weld na ikpokọta components na PCB osisi iji hụ na solder nkwonkwo siri ike na a pụrụ ịdabere na.Jiri teknụzụ mgbago elu elu (SMT) ma ọ bụ teknụzụ ịgbanye nkwụnye, họrọ dabere na ihe achọrọ.Ogo nyocha na ule: A na-eme nyocha na nnwale siri ike n'oge usoro mmepụta iji hụ na bọọdụ PCB mkpịsị aka ọla edo na-ezute nkọwapụta na ihe achọrọ.

Gụnyere nlele anya, ule njirimara eletriki, ule impedance kọntaktị, wdg. Nhicha na mkpuchi: hichaa PCB Goldfinger emechara iji wepụ unyi na ihe fọdụrụ n'elu.A na-eme ọgwụgwọ mkpuchi mgbochi corrosion dị ka achọrọ iji melite nguzogide corrosion nke osisi PCB.Nkwakọ ngwaahịa na nnyefe: Kwakọba PCB mkpịsị aka ọla edo emechara nke ọma iji gbochie mmebi anụ ahụ ma ọ bụ mmetọ.Mgbe emechara nyocha ikpeazụ, nyefee onye ahịa n'oge.Usoro mmepụta osisi PCB Goldfinger chọrọ nhazi dị elu na njikwa siri ike iji hụ na ịdịmma ngwaahịa na nkwụsi ike.Anyị ga-arụ ọrụ siri ike dabere na usoro dị n'elu iji nye gị ngwaahịa PCB mkpịsị aka ọla edo dị elu.