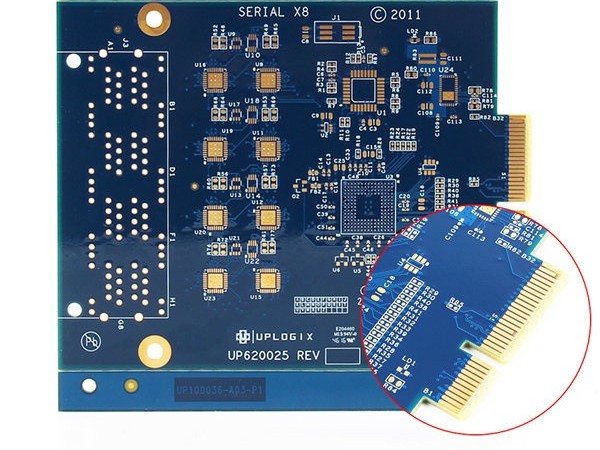

PCB kub ntiv tesxa mus rau ntug metallization kho ib feem ntawmPCB pawg thawj coj saib.

Txhawm rau txhim kho kev ua haujlwm hluav taws xob thiab kev tiv thaiv corrosion ntawm cov khoom sib txuas, cov ntiv tes kub feem ntau siv cov txheej txheem kub plating.Cov hauv qab no yog cov txheej txheem PCB kub ntiv tes kub plating ntau lawm:

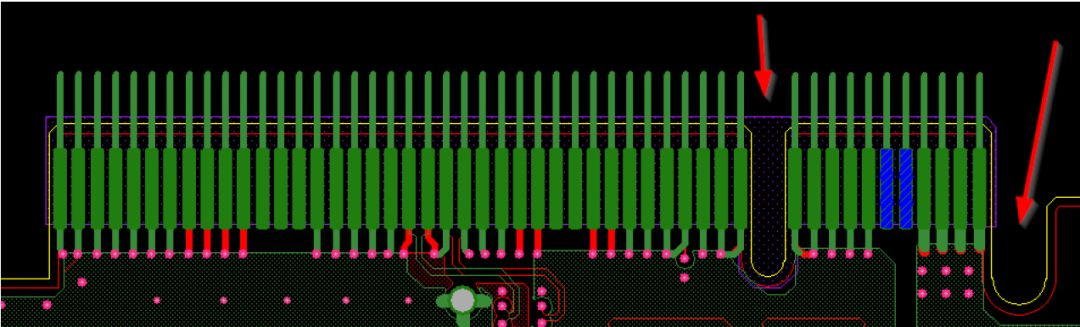

Ntxuav: Ua ntej, cov npoo ntawm lubPCB pawg thawj coj saibyuav tsum tau ntxuav thiab deburred los xyuas kom meej lub smoothness thiab huv si ntawm qhov chaw.

Kev kho deg: Tom ntej no, ntug ntawm PCB yuav tsum tau kho qhov chaw, feem ntau yog los ntawm cov tshuaj tooj liab plating, pickling thiab lwm yam txheej txheem kom tshem tawm cov av thiab oxide txheej hauv kev npaj rau tom ntej kub plating.

Kub plating: Tom qab kev kho deg, cov ntiv tes kub yuav dhau los ntawm cov txheej txheem electroplating.Los ntawm txheej txheej hlau rau ntawmntug ntawm PCB boardthiab siv tam sim no, cov hlau tau muab tso rau saum npoo los ua ib txheej txheej hlau tiv thaiv.

Kev ntxuav thiab kuaj: Tom qab ua tiav kub plating, cov ntiv tes kub yuav tsum tau muab ntxuav kom tshem tawm cov tshuaj seem thiab impurities.Kev tshuaj xyuas zoo yog tom qab ntawd ua kom ntseeg tau tias qhov zoo thiab tuab ntawm txheej txheej metallization ntawm cov ntiv tes kub ua tau raws li qhov yuav tsum tau ua.Cov txheej txheem cov kauj ruam no xyuas kom cov kub plating zoo thiab hluav taws xob ua tau zoo ntawmPCB kub ntiv tes, thaum tseem txhim kho nws cov corrosion kuj thiab kev twb kev txuas stability.

Post lub sij hawm: Mar-07-2024