PCB FACTORY

Mu ne masu sana'a PCB & PCBA manufacturer, samar da PCB Produc-tion, Components Purchasing, SMT da gwajin aiki ga kamfanoni a gida da kuma kasashen waje.

da aka kafa a 2004, muna da namu PCB factory da kuma PCBA factory, bayan wuce da ISO9001, ISO13485, TS16949, UL (E332411).

Muna da sophisticated equipments, ci-gaba da fasaha, m fasaha tawagar, saya tawagar, QC tawagar da management team.Professional software da hardware injiniyoyi wanda zai iya samar da fasaha goyon baya ga customers.We ae a kula da kulawa a lokacin pre-samar, samarwa, da kuma bayan samarwa da kuma goyon bayan fasaha na tallace-tallace & biyo baya.

Babban kasuwanmu shine Turai, Arewacin Amurka, Amurka ta Kudu da sauran ƙasashe.Main samfuran ana amfani da su don kayan lantarki, aikace-aikacen likita, sarrafa masana'antu da kayan wasan yara da dai sauransu..

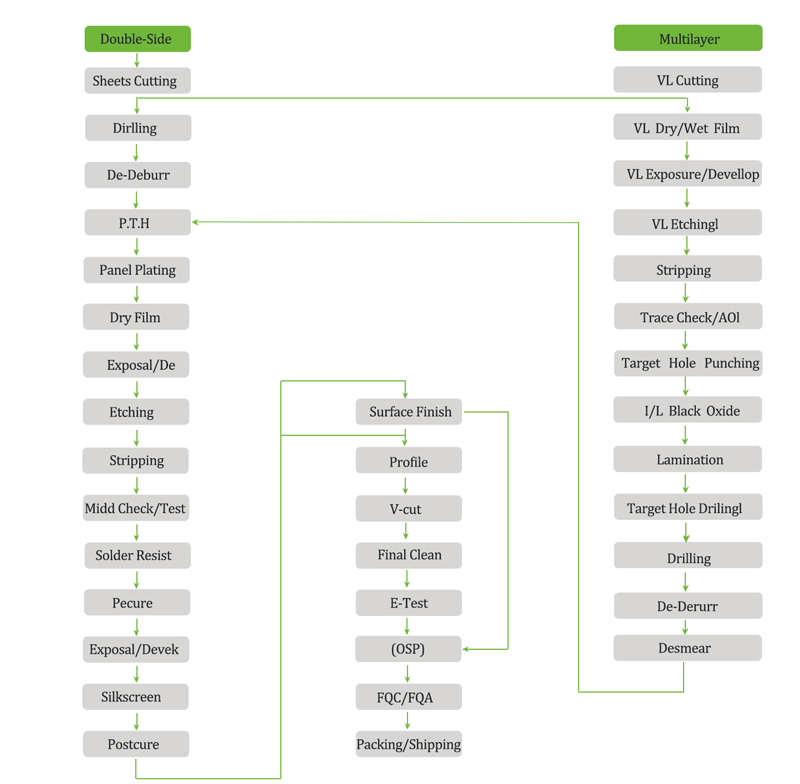

TSARIN PCB

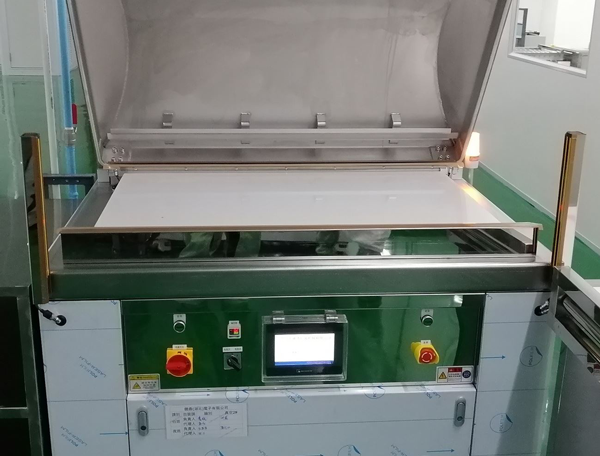

Layin Samar da PCB

Ƙirƙirar ƙaƙƙarfan ƙa'idodin kula da inganci: Kafa cikakken tsarin gudanarwa mai inganci,

Bita na inganci na yau da kullun da tabbatarwa: Ana aiwatar da bita na inganci na yau da kullun na layin samarwa don tabbatar da cewa samfurin ya dace da buƙatun inganci kuma ana aiwatar da madaidaicin daidaitawa da tabbatarwa.

Gabatar da na'urorin gwaji na ci gaba: Yi amfani da na'urorin gwaji na ci gaba, kamar injunan duba X-ray, AOI (Dubawar gani ta atomatik), da sauransu, don gudanar da cikakken gwaji na PCBs don tabbatar da ingancin samfur.

Horowa da ilimi: Samar da horar da ma'aikata da ilimi domin su fahimci ma'auni da buƙatun kamfani kuma su sami ƙwarewar aiki daidai.

Bibiya da saka idanu: Bibiya da saka idanu kowane rukuni na PCBs don tabbatar da daidaito da gano ingancin samfur.

PCB Craft Ability Gabatarwa

| Serial mumber | Abu | Ƙarfin Sana'a |

| 1 | Ƙarshen Sama | Gubar HASL kyauta, Zinare na Zinare, Gilashin Zinare, OSP, Tin Immersion, Immersion |

| azurfa da dai sauransu. | ||

| 2 | Layer | 2-30 yadudduka |

| 3 | Nisa Min Layi | 3 mil |

| 4 | Min Lemun tsami sarari | 3 mil |

| 5 | Min sarari tsakanin kushin zuwa kushin | 3 mil |

| 6 | Min rami diamita | 0.10mm |

| 7 | Min bonding kushin diamita | mil 10 |

| 8 | Matsakaicin girman ramin hakowa da | 01:12.5 |

| allon kauri | ||

| 9 | Matsakaicin girman allon gamawa | 23*35 inci |

| 10 | Rang of finish Baord's Kauri | 0.21-7.0mm |

| 11 | Min kauri na soldermask | 10um |

| 12 | Soldermask | Green,Yellow.Black,Blue,White,Ja,maskar hoto mai kama da gaskiya |

| Mask mai cirewa | ||

| 13 | Min layi na Idents | 4 mil |

| 14 | Min Tsayin Idents | mil 25 |

| 15 | Launi na siliki-allon | Fari, rawaya, baki |

| 16 | Tsarin fayil ɗin bayanai | FILE GEBER da FILE DRILUNG, PROTEL SERIES, SERIES PADS2000, Powerpcb |

| ≤FR1ES.CYDB÷ | ||

| 17 | E-Gwajin | 100% E-Gwaji; Gwajin Ƙarfin Ƙarfi |

| 18 | Material don PCB | FR-4, High TG FR4, Halogen free, Rogers, CEM-1 Arlon, Taconic, PTFE, Isola da dai sauransu |

| 19 | Sauran gwajin | Gwajin Tashin hankali, Gwajin Juriya, Microsection da dai sauransu |

| 20 | Bukatar fasaha ta musamman | Makaho &Binne Vias da Babban Kauri |

PCB gwajin lantarki

GWAJIN FLYING

A cikin ƴan shekarun da suka gabata, gwajin allura mai tashi ya zama hanyar gwaji da ta fi shahara idan aka kwatanta da gwajin kan layi na PCBA na gargajiya saboda ƙarancin ƙira da buƙatun ƙira da kawar da mafi girman kayan aiki da farashin shirye-shirye.

Gwajin allura mai tashi baya buƙatar ƙayyadaddun kayan gwajin gwaji kuma ana iya tsara shi cikin sauƙi don dacewa da shimfidu da ƙira na PCBA daban-daban, yin gwajin allura mai tashi ya zama mafita mai tsada akan layi don ƙanana da matsakaicin tsari gami da taron samfuri.

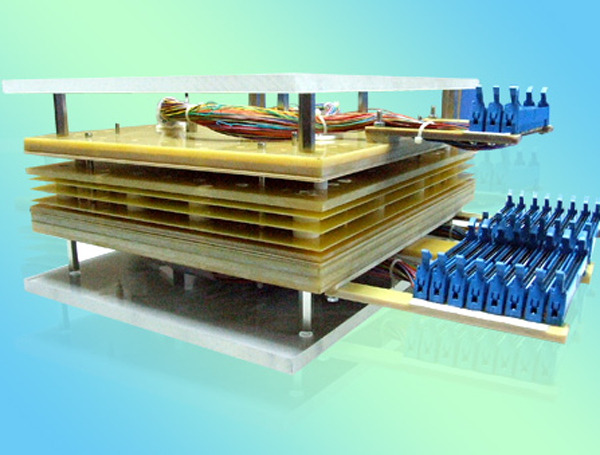

PCB gwajin tara

PCB batch test fixture, wanda kuma ake kira PCB test tara, kayan aiki ne da ake amfani dashi don gwajin tsari na allunan PCB.Yawanci ya ƙunshi ƙayyadaddun shirye-shiryen allo, wayoyi masu haɗawa da kewayawa, fil ɗin gwaji, da sauransu. PCB batch gwajin kayan aikin ana amfani da su musamman don haɓaka ingantaccen samarwa da ingancin gwaji na allon PCB.Yana iya haɗa allunan PCB da yawa a lokaci guda kuma ya gudanar da gwajin siginar lantarki akan allunan PCB ta hanyar fil ɗin gwaji.Yin amfani da na'urar gwajin batch na PCB, da farko gyara allon PCB akan madaidaicin farantin karfen na'urar, sa'an nan kuma haɗa na'urar zuwa kayan gwajin ta hanyar wayar haɗin kewaye.

Kayan aikin gwaji yawanci sun haɗa da janareta na sigina, masu nazarin dabaru, na'urori masu yawa, da sauransu. Yayin aikin gwajin, kayan gwajin za su aika da siginar lantarki zuwa fil ɗin gwaji na kwamitin PCB, kuma za a bincika sakamakon gwajin da yin rikodin ta kayan aiki kamar dabaru. nazari.Ta hanyar gwajin batch na kayan aiki, matsalolin lantarki akan allon PCB ana iya gano su cikin sauri da daidai, haɓaka ingancin samfur da ingantaccen samarwa.A takaice, PCB batch gwajin tsayarwa ne mai matukar m kayan aiki da za su iya taimaka tsari gwajin allon PCB da inganta gwaji inganci da inganci.

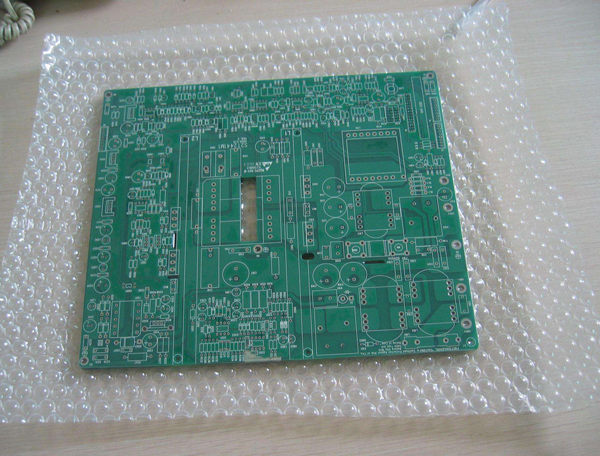

Kunshin

Anan akwai wasu la'akari don marufi na PCB waɗanda muke rabawa tare da ku: